Our Capabilities & Investigationes

Everyday steel's Technology & Durability

Everyday Steel ™ in a strong corrugated profile and are stiffened with unique ‘W’ stiffeners with much higher strength and reliability than normal one. Our unique profiled technology of uniform pitch and depth makes it a premium one as it acts as a structural reinforcement and shock absorber for earth movement or soil subsidence.

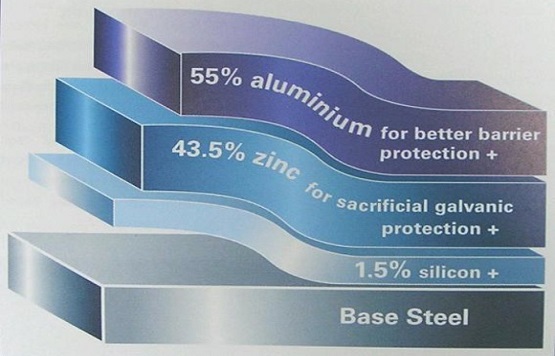

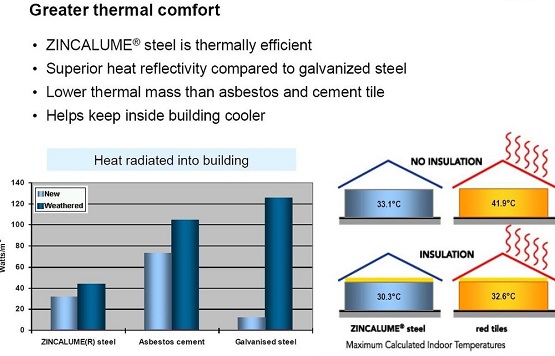

Zincalume steel was first released by BlueScope steel in 1976 and very quickly replaced Galvanized steel in the construction market largely due to Zincalume superior corrosion resistance and long life; Zincalume has 4 times the life of Galvanized steel;The composition in which the steel sheets are dipped is made up of 55% aluminum, 43.5% zinc and 1.5% silicon. This coating is done at a temperature of 600C and combines superior corrosion resistance of aluminum with the cut edge protection of zinc. Material used in tanks & silos are ZINCALUME® Steel manufactured by Tata Bluescope; an equal joint venture between Tata Steels Ltd. and Bluescope Steels of Australia.Our ZINCALUME® steel has both the galvanic/sacrificial protection and barrier protection which makes it the most preferred option for roofing and walling applications around the world.

ZINCALUME® Steel has an alloy coating weight of 55% Aluminum (80% by Volume), 43.5% Zinc & 1.5% Silicon with 150gram/m2 coating weight is distributed equally on both sides of the coated strip. These sheets worldwide have set the standard for corrosion resistance and long life and are manufactured as per Australian Standard AS 1397:2002, American Standard ASTM A792M and Indian Standards IS 15961:2012 & ISO 9364. We provide ZINCALUME® steel which is extensively tested in laboratory and in actual conditions, to evaluate its corrosion resistance performance in different environments. It is particularly preferred for the tropical climates and marine environments.

.jpeg)